If you’re new to thermoplastics, start with common sheets like acrylic, polycarbonate, or PETG, which are easy to cut and shape. Use sharp tools, safety gear, and work in ventilated areas. Techniques like heat bending, gluing, and cutting with proper tools help you create projects confidently. Keep your sheets well-maintained and troubleshoot issues like warping or scratches. Explore simple crafts and tips, and you’ll quickly build skills to tackle more complex designs.

Key Takeaways

- Choose beginner-friendly thermoplastic sheets like acrylic or PETG for easy shaping and clear results.

- Use proper tools such as utility knives and heat guns, following safety protocols to ensure clean cuts and safe handling.

- Heat sheets evenly for bending and shaping, controlling temperature to prevent warping or bubbling.

- Prepare surfaces thoroughly before gluing with compatible adhesives and roughening for strong joins.

- Start with simple projects like keychains and jewelry to develop skills in heating, shaping, and finishing techniques.

Common Types of Thermoplastic Sheets

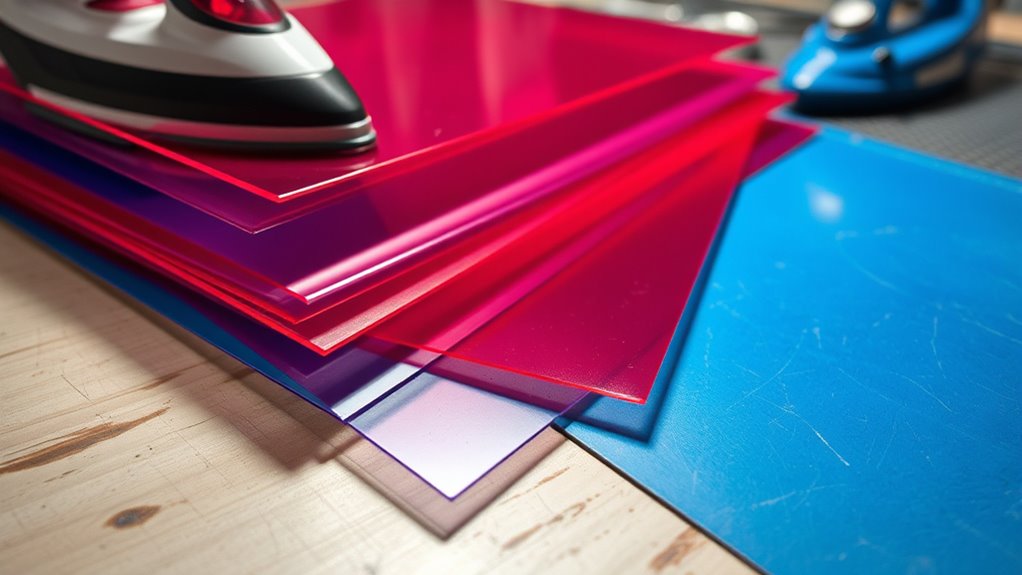

Thermoplastic sheets come in several common types, each suited for different applications. You’ll find various types of thermoplastic, such as acrylic, polycarbonate, PVC, and PETG, each offering unique properties. These materials are available in a range of sheet thicknesses, from thin 1mm sheets to robust 10mm or thicker options. Thinner sheets are ideal for detailed projects and lightweight signs, while thicker sheets provide durability and impact resistance. Understanding the different types of thermoplastic helps you choose the right material for your project. Consider how flexible or rigid you need the sheet to be, along with its clarity or color options. Color accuracy impacts the visual appeal of finished projects, especially when precise color matching is needed. By selecting appropriate sheet thicknesses and types, you’ll ensure your project’s success and longevity.

Essential Tools and Safety Tips

To work safely with thermoplastics, you need the right tools and proper safety gear. Choosing the appropriate cutting and heating tools helps prevent accidents, while wearing protective equipment keeps you safe from hot materials and debris. Keep your workspace organized and follow safety measures to guarantee a smooth, injury-free project. Additionally, being aware of essential oils for safety can help you create a comfortable and hazard-free environment during your work.

Proper Tool Selection

Choosing the right tools is crucial for working safely and effectively with thermoplastics. Proper tool selection ensures clean cuts, precise shaping, and minimizes damage to the material. It also helps prevent accidents. When selecting tools, prioritize quality and suitability for the task. Remember, safety equipment complements your tools and is indispensable for protection. Consider the following:

- Sharp utility knives for clean trimming

- Heat guns with adjustable temperature controls

- Clamps to hold sheets securely

- Fine-tooth saws for detailed cuts

- Protective gloves and goggles for safety

Using the appropriate tools can also facilitate better results in thermoplastic projects, ensuring your work is both efficient and safe. Always inspect your tools before use and ensure your safety equipment is in good condition. Proper tool selection is a key step in mastering thermoplastic projects.

Personal Protective Equipment

Are you aware of the essential protective gear needed when working with thermoplastics? Personal protective equipment (PPE) is vital to keep you safe from heat, fumes, and sharp edges. Always wear safety gear like gloves to protect your hands from hot surfaces and potential cuts. Safety goggles are a must to shield your eyes from splashes or flying debris. A dust mask or respirator helps prevent inhaling fumes or particles, especially during heating or sanding. Long sleeves and an apron protect your skin from burns and stains. Remember, PPE isn’t optional—it’s your first line of defense against accidents. Before starting any project, check your safety gear to verify it’s in good condition. Proper PPE helps you work confidently and safely with thermoplastics. Additionally, being aware of bicycle tire longevity in storage can help prevent accidents caused by degraded materials.

Workspace Safety Measures

Ensuring a safe workspace is essential when working with thermoplastics, and having the right tools and safety measures in place makes all the difference. A proper workspace setup helps you identify hazards early and prevent accidents. Start by organizing your tools to minimize clutter and guarantee easy access. Always keep a fire extinguisher nearby, as melting plastics can pose fire risks. Use ventilation or exhaust systems to avoid inhaling fumes, and wear appropriate protective gear. Regularly inspect your equipment for damage or wear to prevent malfunctions. Remember, hazard identification is key to maintaining a safe environment. By following these safety tips, you reduce risks and create a workspace that supports efficient, safe thermoplastic work. Incorporating proper storage solutions can also help keep your workspace organized and safe.

Cutting Techniques for Thermoplastics

When cutting thermoplastics, choosing a sharp tool makes the process smoother and safer. Keep your cutting speed steady to prevent melting or cracking the material. Always follow safety precautions, like wearing gloves and eye protection, to avoid injuries during the cutting process.

Sharp Tool Selection

Choosing the right cutting tools is essential for achieving clean, precise edges when working with thermoplastics. Sharp tool selection guarantees smooth cuts and minimizes material distortion. Use precision blades designed specifically for thermoplastics to get clean, accurate results. Always wear safety gloves to protect your hands from sharp edges and accidental slips. Opt for tools with fine, sharp blades rather than dull or blunt ones, which can cause jagged edges or tearing. Keep tools sharp and well-maintained, and choose the correct blade type based on your project. Remember, a good cut begins with the right tools and proper safety measures. Prioritize quality over cost to ensure consistent, professional results in your thermoplastics projects. Additionally, understanding support hours can help you plan your work sessions around times when assistance or resources are most accessible.

Cutting Speed Tips

To achieve clean, precise cuts in thermoplastics, controlling your cutting speed is essential. Moving too quickly increases the cutting force, which can cause jagged edges and excessive blade heat. Conversely, cutting too slowly may generate unnecessary blade heat, risking melting or warping the material. Find a steady, moderate cutting speed that maintains smooth motion without forcing the blade through the plastic. This helps keep blade heat in check, preventing it from transferring to the sheet and causing deformation. Pay attention to your tool’s response; if you notice the blade heating up or the material melting, slow down. Consistent, controlled cutting speed guarantees cleaner cuts, preserves the sheet’s integrity, and prolongs your tool’s lifespan. Additionally, using appropriate cutting tools designed for thermoplastics can further enhance your results and reduce the risk of damage.

Safety Precautions

Safety precautions are crucial whenever you’re cutting thermoplastics to prevent injuries and damage. Always work in a well-ventilated area to minimize chemical hazards from fumes released during cutting. Keep a fire extinguisher nearby, as sparks or overheating can pose fire safety risks. Use sharp blades to ensure clean cuts and reduce the chance of slips. Wear safety goggles and gloves to protect your eyes and hands from shards and hot surfaces. Additionally, avoid wearing loose clothing that could catch on equipment. Properly secure the sheet before cutting to maintain control. Remember, awareness of chemical hazards and fire safety protocols helps prevent accidents, ensuring a safer and more efficient cutting process. Understanding safety precautions is essential for beginners to work confidently and avoid common hazards.

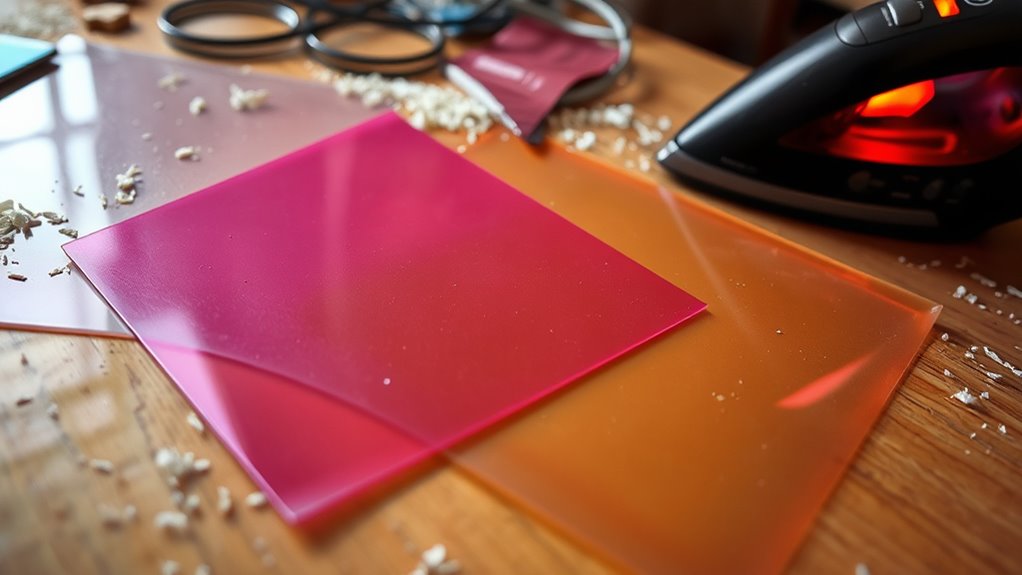

Bending and Shaping Methods

Bending and shaping thermoplastics requires careful heating and proper techniques to achieve desired forms without cracking or warping. Heat bending involves evenly warming the sheet until it becomes pliable, then shaping it by hand or using molds. Rotary shaping uses tools like a lathe or rotating forms to create curves or cylindrical shapes. To prevent damage, monitor temperature carefully and avoid overheating. Proper technique ensures a smooth, professional finish. Here’s a quick comparison:

| Method | Suitable for | Key Advantage |

|---|---|---|

| Heat Bending | Flat or simple curves | Precise control of shape |

| Rotary Shaping | Cylinders, rounded objects | Uniform curves and smooth surfaces |

| Both Methods | Custom, detailed projects | Flexibility in design |

| Caution | Overheating can cause warping | Use temperature controls |

Additionally, understanding the automation techniques used in manufacturing can help optimize the shaping process for better efficiency and quality.

Gluing and Joining Thermoplastic Pieces

Gluing and joining thermoplastic pieces is a straightforward process that requires proper surface preparation and the right adhesive. To guarantee strong, durable bonds, choose from various adhesive types like solvent-based glues, epoxy, or hot air welders. Surface cleaning and roughening improve adhesion and joint strengthening. Consider the following factors:

- Compatibility of adhesive types with your thermoplastic material

- Surface preparation techniques for ideal bonding

- Temperature and curing time requirements

- Techniques for applying adhesives evenly

- Methods for testing joint strength after bonding

Additionally, understanding the emotional support needs of individuals involved can help improve collaboration and reduce conflicts during the bonding process.

Basic Projects to Get Started

Getting started with simple thermoplastic projects is a great way to build your skills and confidence. Creative project ideas like making keychains, jewelry, or small decorative items are perfect for beginners. Use beginner-friendly techniques such as heating the sheet with a heat gun or boiling water, then shaping it with molds, templates, or your hands. These projects allow you to experiment with different colors, thicknesses, and textures without feeling overwhelmed. Start with simple designs and gradually try more complex shapes as you gain experience. Not only will these projects help you learn basic heating, shaping, and finishing skills, but they also give you a sense of accomplishment. With a little practice, you’ll be ready to take on more advanced thermoplastic creations. Exploring creative expression through thermoplastics can inspire you to develop unique and personalized items.

Troubleshooting Common Challenges

Even experienced crafters encounter challenges when working with thermoplastics, but understanding common issues can help you troubleshoot effectively. One frequent problem is warping caused by thermal expansion, which occurs if the material is heated unevenly or cooled too quickly. Surface defects like bubbles, scratches, or cloudiness can also appear, often due to contaminants or improper handling. To prevent these issues, consider the following:

- Ensure uniform heating to minimize thermal expansion

- Use a clean workspace to prevent surface defects

- Avoid rapid cooling to reduce warping

- Properly sand or clean sheets before shaping

- Monitor temperature closely during heating and molding

- Recognize the importance of material properties in achieving optimal results.

Recognizing these challenges helps you refine your techniques and achieve professional results.

Tips for Maintaining and Caring for Your Sheets

Proper maintenance is essential to keep your thermoplastic sheets in top condition and guarantee they last through many projects. To prevent warping or damage, store sheets flat in a cool, dry place away from direct sunlight. Use protective coverings like foam or cardboard to avoid scratches. For cleaning, gently wipe with a soft cloth and mild soap; avoid abrasive cleaners that can scratch the surface. Here’s a quick guide:

| Storage Tips | Cleaning Methods | Common Mistakes |

|---|---|---|

| Keep flat and dry | Use mild soap and water | Using harsh chemicals |

| Avoid sunlight | Avoid abrasive scrubbers | Storing improperly |

| Support with padding | Wipe gently, no pressure | Ignoring temperature |

| Keep covered | Dry thoroughly after cleaning | Not checking for damage |

| Store away from heat | Regularly inspect sheets | Ignoring surface issues |

Additionally, protecting your sheets from temperature fluctuations can help prevent warping and extend their lifespan.

Frequently Asked Questions

Can Thermoplastics Be Painted or Decorated Easily?

Yes, thermoplastics can be painted or decorated easily. You can use various painting techniques like spray paint, acrylics, or markers to add color and designs. Decorative options include applying decals, stencils, or even embedding materials for texture. Just make sure the surface is clean and primed if needed, and choose compatible paints for best adhesion. This way, you can customize your thermoplastic projects with ease.

What Are the Best Storage Practices for Thermoplastic Sheets?

To guarantee storage safety and maximize material longevity, store thermoplastic sheets flat in a cool, dry place away from direct sunlight and heat sources. Keep them in a protective covering or sealed container to prevent dust and moisture damage. Avoid stacking too high to prevent warping, and handle sheets carefully to prevent scratches or dents. Proper storage protects your investment and keeps your thermoplastics in prime condition for future use.

How Heat-Resistant Are Different Types of Thermoplastics?

You’ll find that different thermoplastics vary in thermal resistance; for example, polycarbonate offers high durability and can withstand temperatures up to 140°C, making it suitable for heat-exposed applications. PVC has moderate thermal resistance, while HDPE is less heat-resistant but highly durable. Understanding each material’s thermal resistance helps you choose the right thermoplastic for your project, ensuring its durability under heat conditions.

Are There Eco-Friendly or Recycled Thermoplastic Options?

Yes, there are eco-friendly options in thermoplastics. You can choose recycled materials like recycled PET or HDPE, which reduce waste and environmental impact. These recycled thermoplastics are often used in sheets for various projects, making them ideal for eco-conscious choices. By opting for recycled or biodegradable thermoplastics, you support sustainability and help minimize plastic pollution while still benefiting from versatile, durable materials.

How Do I Identify the Correct Thermoplastic for My Project?

You’re on the right track by doing your homework first. To identify the correct thermoplastic, consider your project’s material compatibility—make sure the plastic suits your application’s environment and stress levels. Check the thickness measurement to ensure it provides the durability you need. Don’t be afraid to ask suppliers for guidance or samples. When everything lines up, you’ll have a product that’s a perfect fit like a glove.

Conclusion

Now that you know the basics of working with thermoplastics, are you ready to start your own projects? With the right sheets, tools, and techniques, you can create everything from simple crafts to complex designs. Remember to stay safe and patient as you learn. So, why wait? Jump in, experiment, and see what amazing things you can make with these versatile materials!